060000 - Wood

Fasteners for Treated Lumber - Issue 06

- Corey S Zussman, AIA

- Link

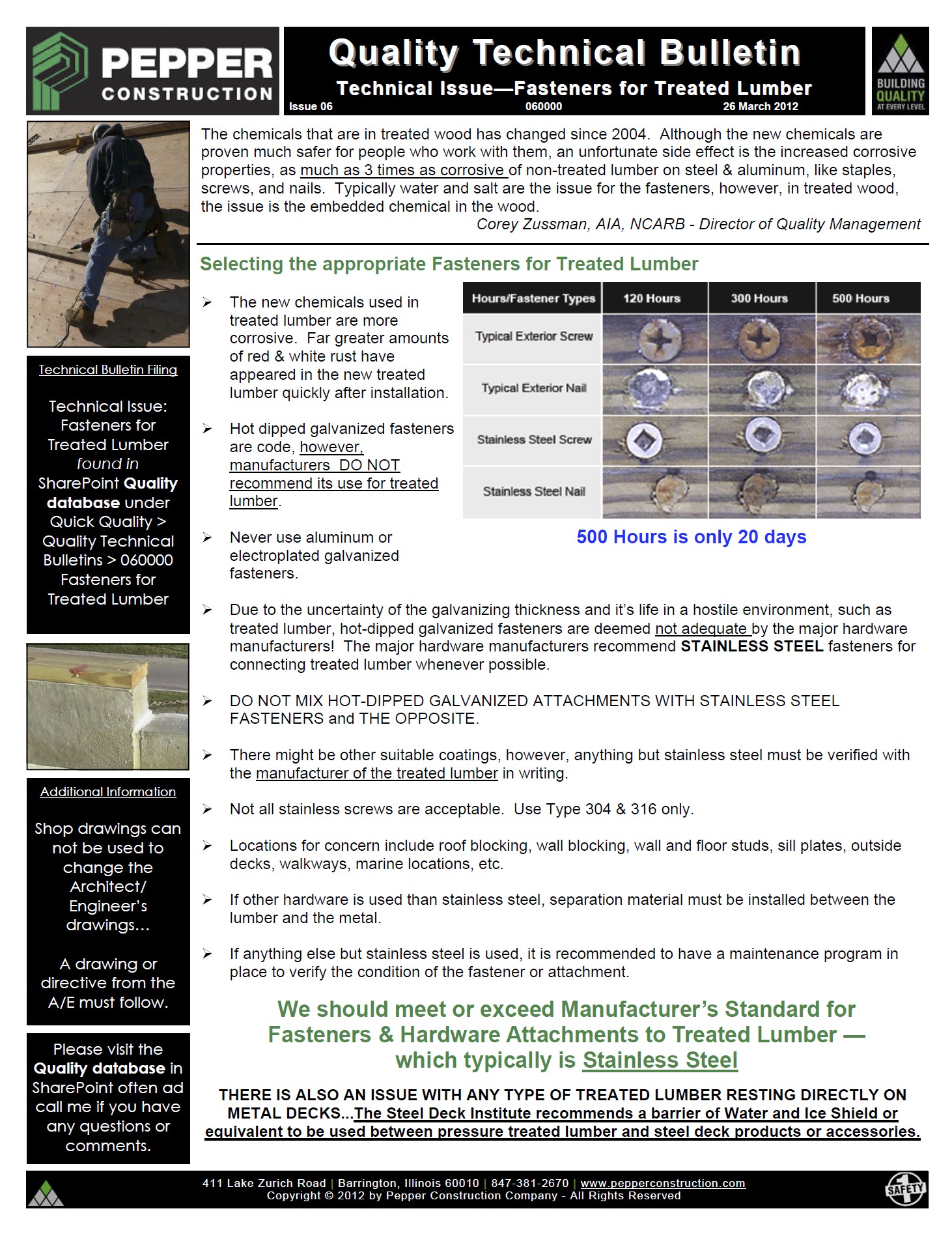

The chemicals that are in treated wood has changed since 2004. Although the new chemicals are proven much safer for people who work with them, an unfortunate side effect is the increased corrosive properties, as much as 3 times as corrosive of non-treated lumber on steel & aluminum, like staples, screws, and nails. Typically water and salt are the issue for the fasteners, however, in treated wood, the issue is the embedded chemical in the wood.

Treated Wood on Metal Deck - Issue 07

- Corey S Zussman, AIA

- Link

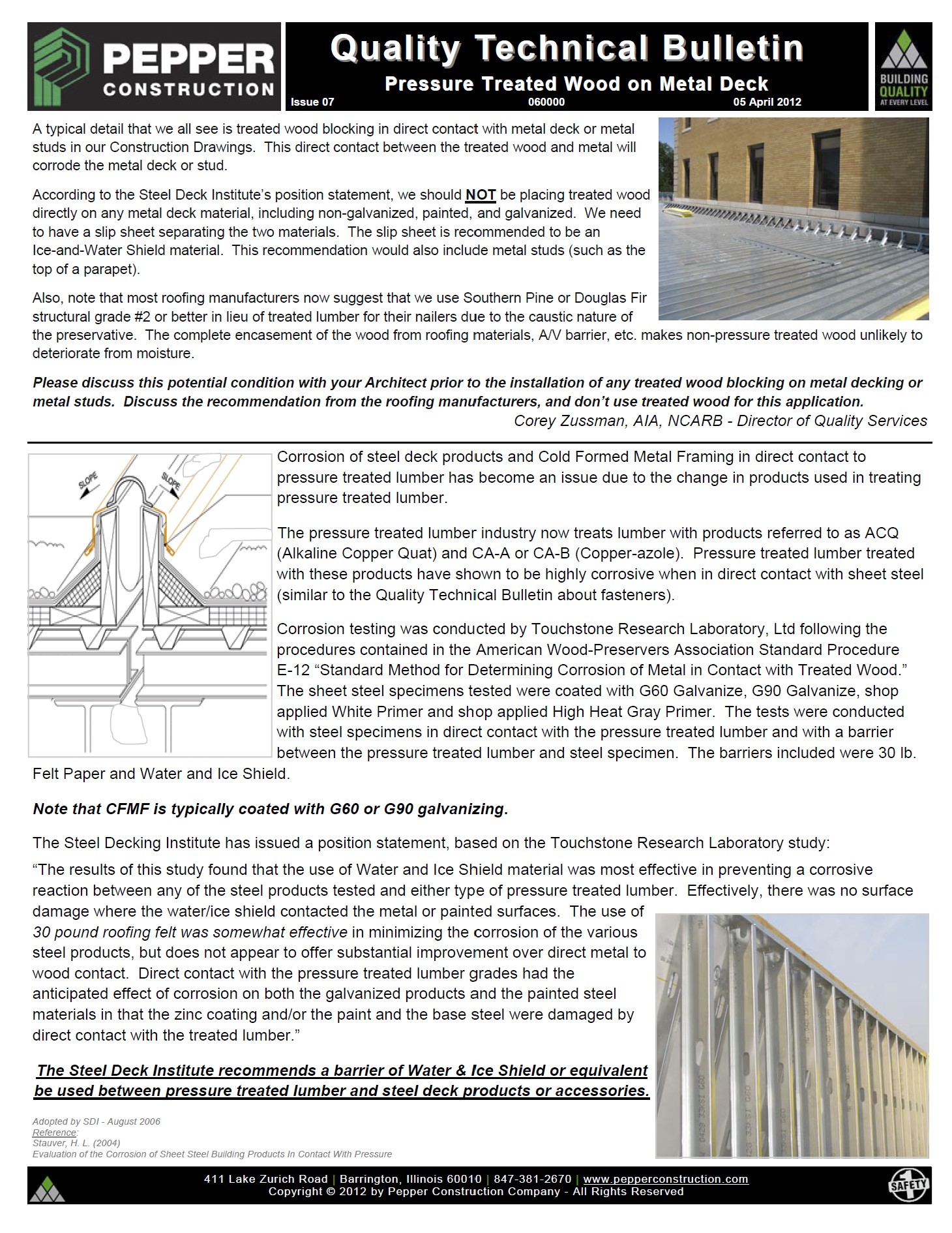

A typical detail that we all see is treated wood blocking in direct contact with metal deck or metal studs in our Construction Drawings. This direct contact between the treated wood and metal will corrode the metal deck or stud.

FRT Wood - Issue 36

- Corey S Zussman, AIA

- Link

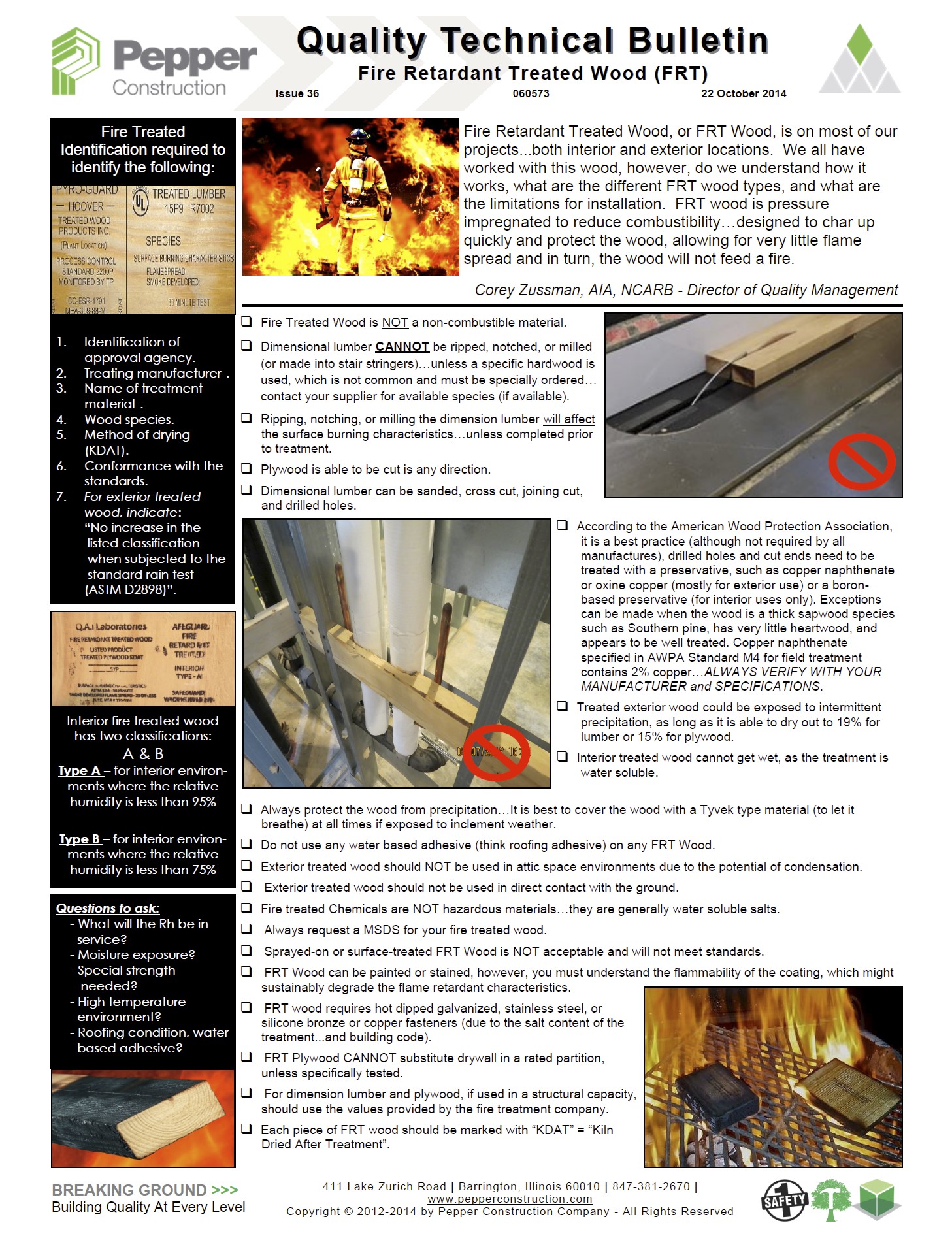

Fire Retardant Treated Wood, or FRT Wood, is on most of our projects...both interior and exterior locations. We all have worked with this wood, however, do we understand how it works, what are the different FRT wood types, and what are the limitations for installation. FRT wood is pressure impregnated to reduce combustibility…designed to char up quickly and protect the wood, allowing for very little flame spread and in turn, the wood will not feed a fire.

Plywood Edge Blocking 01 - QN

- Corey S Zussman, AIA

- Link

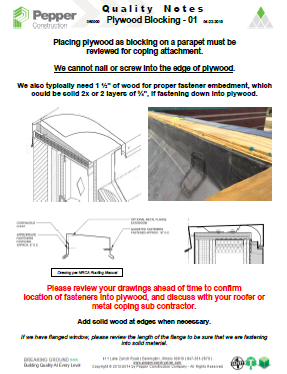

Placing plywood as blocking on a parapet must be reviewed for coping attachment.

Roof Blocking Detailing 01 - QN

- Corey S Zussman, AIA

- Link

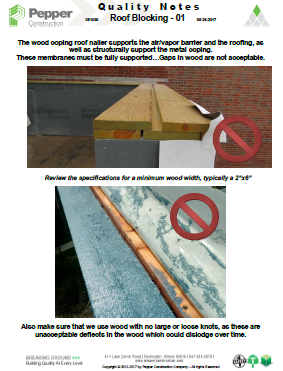

The wood coping roof nailer supports the air/vapor barrier and the roofing, as well as structurally support the metal coping. These membranes must be fully supported. Gaps in wood are not acceptable.

PT Wood Blocking 01 - QN

- Corey S Zussman, AIA

- Link

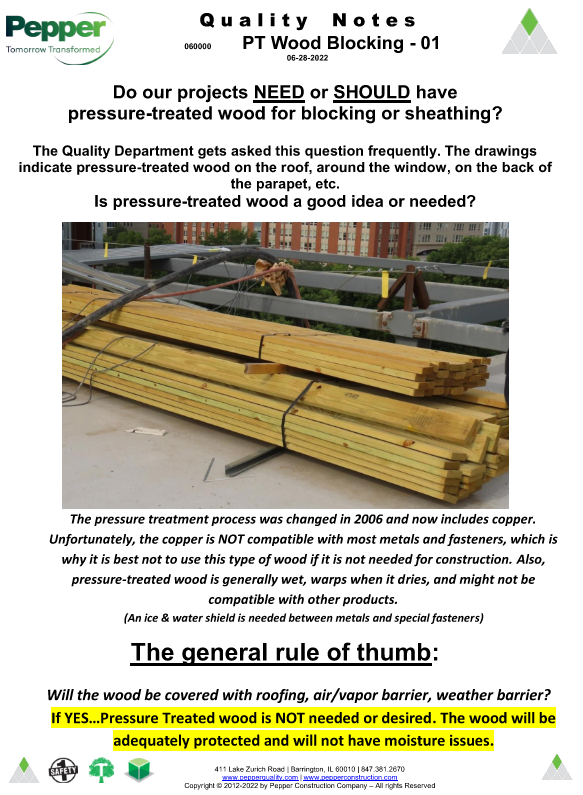

Do our projects NEED or SHOULD have pressure-treated wood for blocking or sheathing? The Quality Department gets asked this question frequently. The drawings indicate pressure-treated wood on the roof, around the window, on the back of the parapet, etc. Is pressure-treated wood a good idea or needed?

Millwork Ceiling Clips 01 - QN

- Corey S Zussman, AIA

- Link

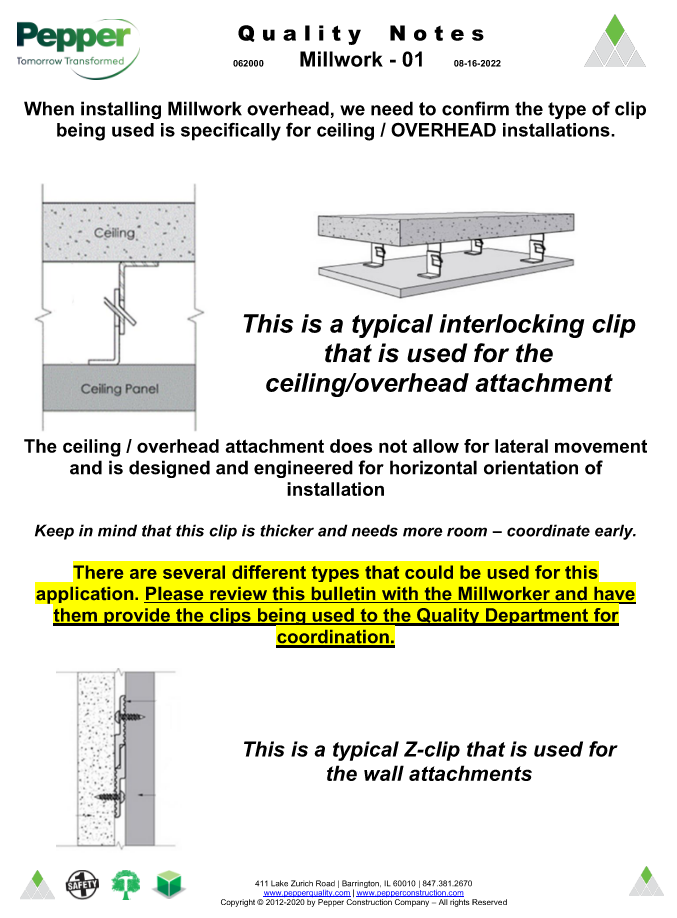

When installing millwork overhead, we need to confirm the type of clip being used is specifically for ceiling / OVERHEAD installations. The ceiling / overhead attachment does not allow for lateral movement and is designed and engineered for horizontal orientation of installation. Keep in mind that this clip is thicker and needs more room – coordinate early. There are several different types that could be used for this application. Please review this bulletin with the Millworker and have them provide the clips being used to the Quality Department for coordination.

Proper Storage and Installation Millwork Environment - Issue 68

- Corey S Zussman, AIA

- Link

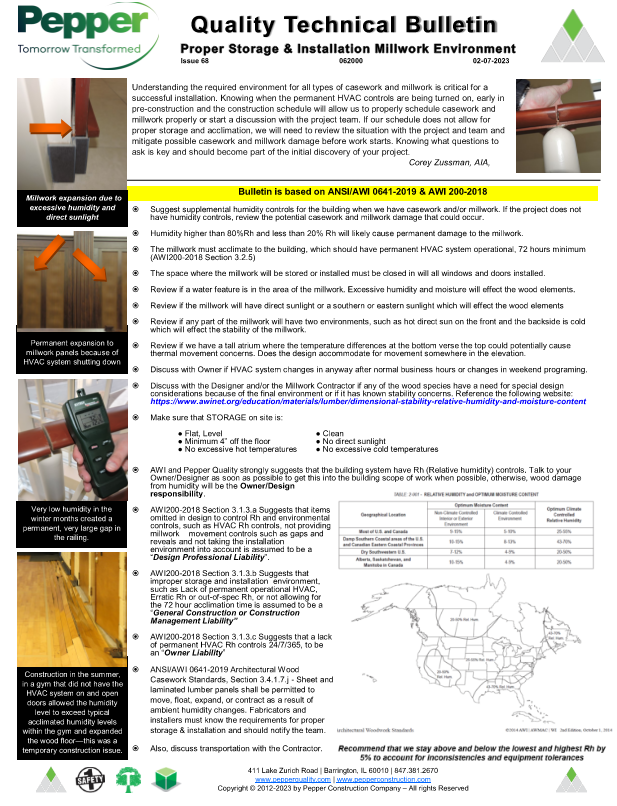

Understanding the required environment for all types of casework and millwork is critical for a successful installation. Knowing when the permanent HVAC controls are being turned on, early in pre-construction and the construction schedule will allow us to properly schedule casework and millwork properly or start a discussion with the project team. If our schedule does not allow for proper storage and acclimation, we will need to review the situation with the project and team and mitigate possible casework and millwork damage before work starts. Knowing what questions to ask is key and should become part of the initial discovery of your project.

Wood Storage Concerns QN

- Corey S Zussman, AIA

- Link

When we are storing material on the interior or exterior and we are required to cover the material, we need to make sure that the cover material is “BREATHABLE” or has a high “PERM” rating per ASTM E96…Method A for interior and Method B for exterior.