040000 - Masonry

Cleaning Masonry - Issue 42

- Corey S Zussman, AIA

- Link

Cleaning masonry, concrete, and stone should never be taken lightly. All materials will react differently to different cleaning solutions. Issues with the durability and final color of the masonry or concrete product will vary greatly depending on the product used and the process to clean. And finally, workmanship plays a big role in the overall final quality of the product, cleaning as the masonry is being installed is paramount to a good, long-lasting installation with less effort cleaning overall, thus producing a high quality, long lasting project.

Masonry Wall Flashing - Issue 50

- Corey S Zussman, AIA

- Link

Flashing is one of the most important pieces of a wall assembly. If the flashing is not installed correctly, per the manufacturer’s instructions, the wall system will likely fail. A common flashing product is the rubberized asphalt wall flashing. There are certain details and temperatures which we all should follow when we install this product. We must remember that quality is in the details and installing flashing is no exception.

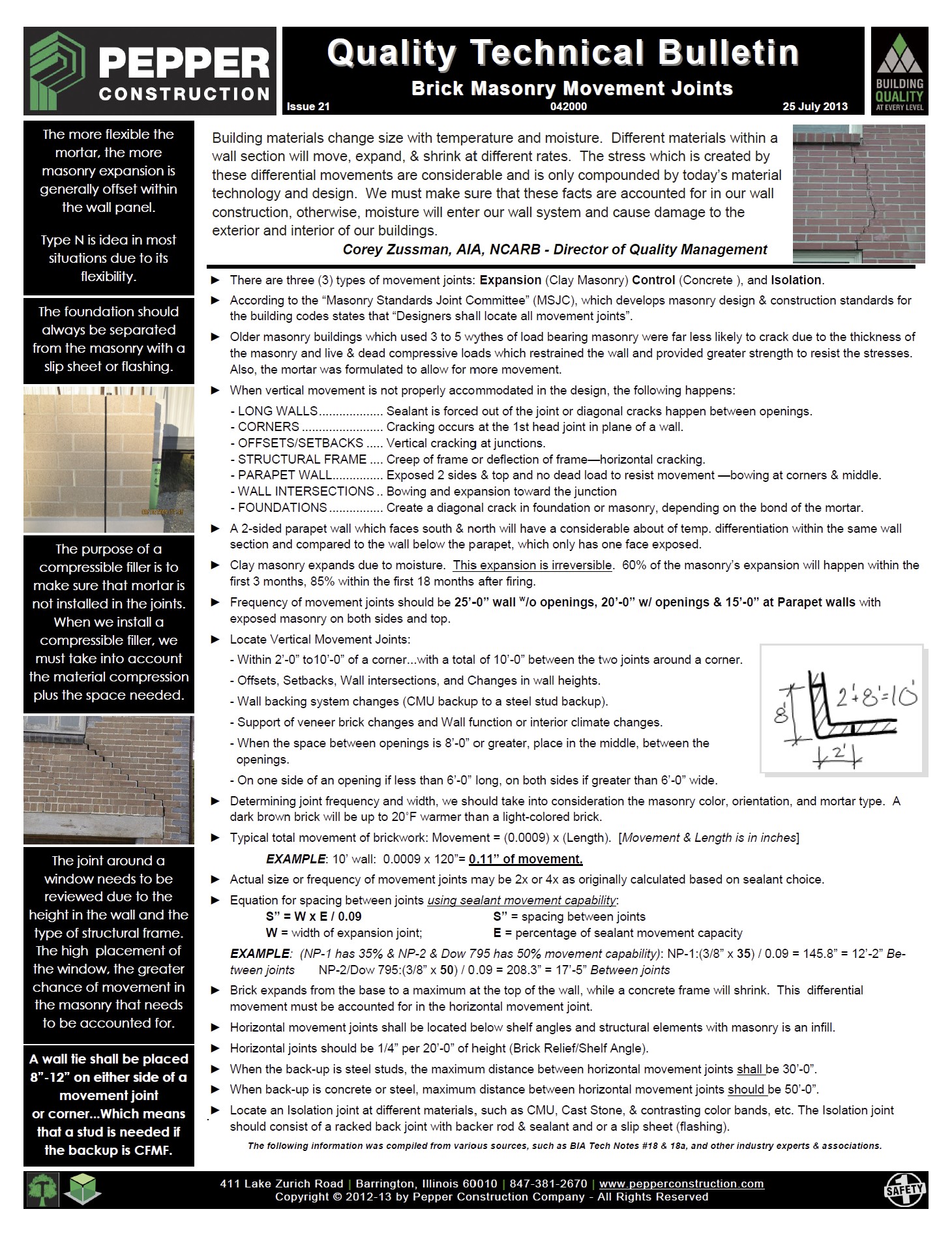

Brick Masonry Movement Joints - Issue 21

- Corey S Zussman, AIA

- Link

Building materials change size with temperature and moisture. Different materials within a wall section will move, expand, & shrink at different rates. The stress which is created by these differential movements are considerable and is only compounded by today’s material technology and design. We must make sure that these facts are accounted for in our wall construction, otherwise, moisture will enter our wall system and cause damage to the exterior and interior of our buildings.

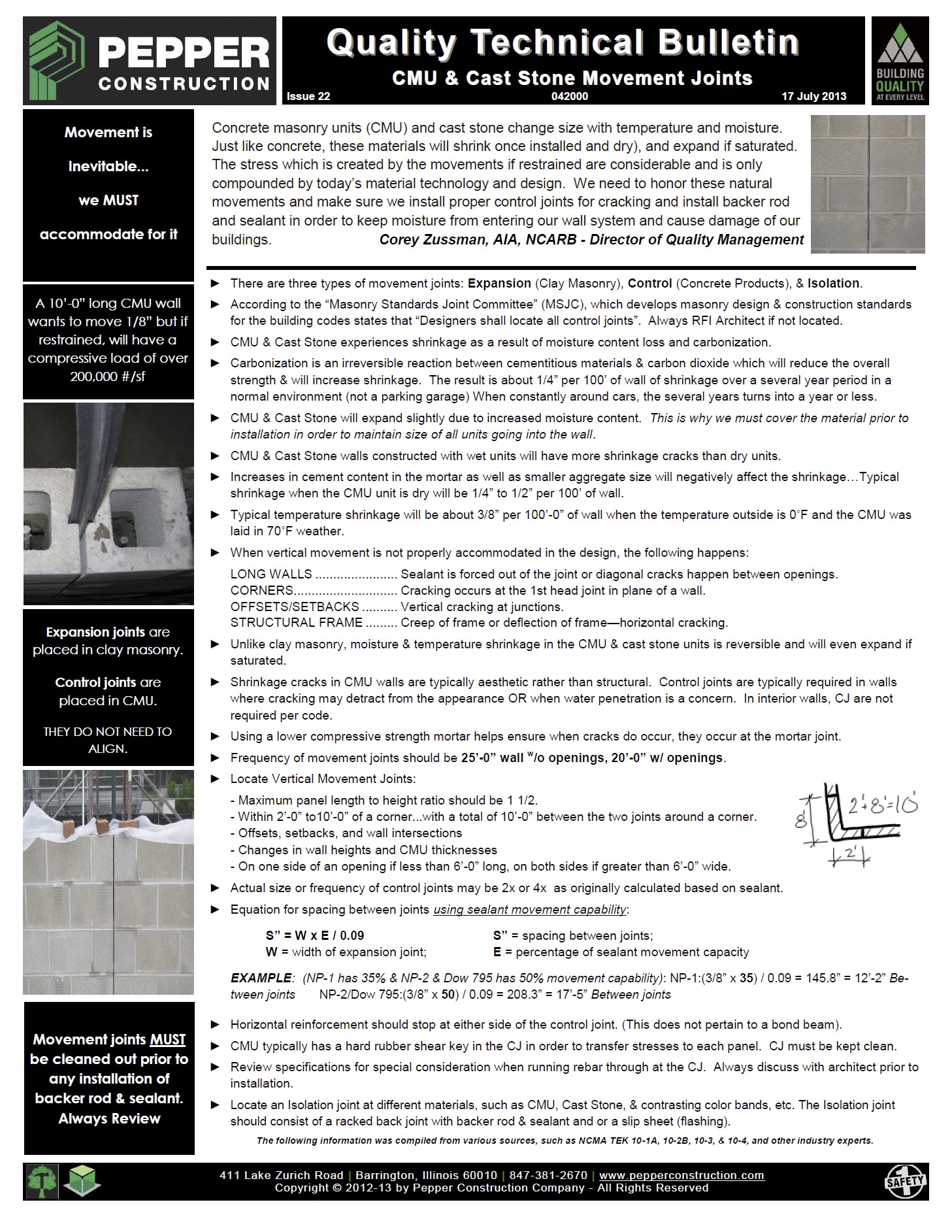

CMU Cast Stone Movement Joints - Issue 22a

- Corey S Zussman, AIA

- Link

Concrete masonry units (CMU) and cast stone change size with temperature and moisture. Just like concrete, these materials will shrink once installed and dry), and expand if saturated. The stress which is created by the movements if restrained are considerable and is only compounded by today’s material technology and design. We need to honor these natural movements and make sure we install proper control joints for cracking and install backer rod and sealant in order to keep moisture from entering our wall system and cause damage of our buildings.

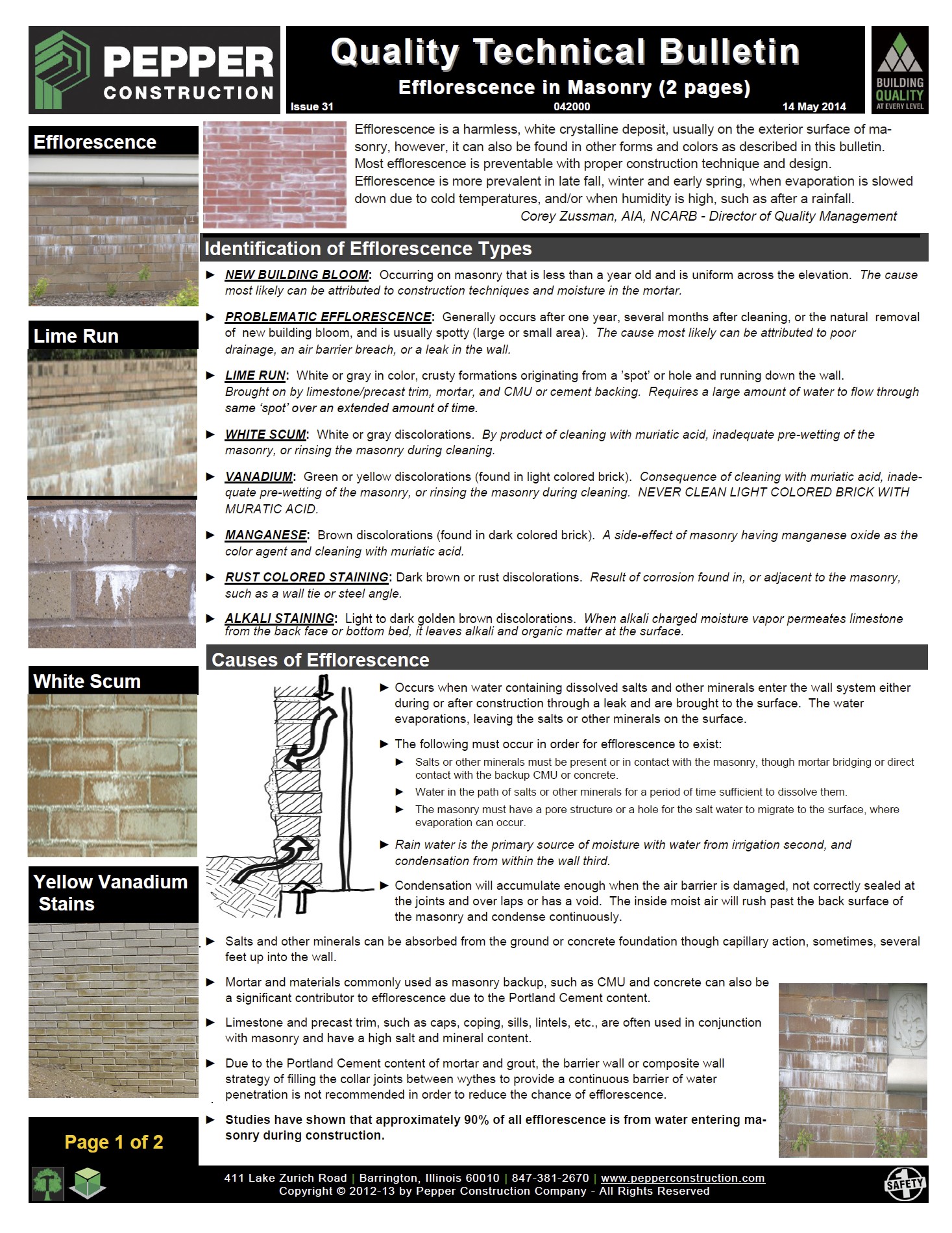

Masonry Efflorescence - Issue 31

- Corey S Zussman, AIA

- Link

Efflorescence is a harmless, white crystalline deposit, usually on the exterior surface of masonry, however, it can also be found in other forms and colors as described in this bulletin.Most efflorescence is preventable with proper construction technique and design. Efflorescence is more prevalent in late fall, winter and early spring, when evaporation is slowed down due to cold temperatures, and/or when humidity is high, such as after rainfall.

Tuckpointing - Issue 47

- Corey S Zussman, AIA

- Link

Tuckpointing is the process of removing defective mortar and installing fresh, new mortar. Tuckpointing masonry improves weather resistance, reduces water penetration, maintains structural and visual integrity, and prolongs the life of the wall. Every project differs in some way; the type of masonry, the bonding and coursing, the mortar joint size and shape, and the type of mortar that was and is to be used in the wall. Each characteristic of the wall must be taken into account prior to starting the job, and this includes selecting the type of equipment that we use on the wall. In the end, success depends on you, the tuckpointer, as your experience and knowledge about craft is as important as the correct specifications. Patience and craftsmanship will produce a successful project that would all be proud.

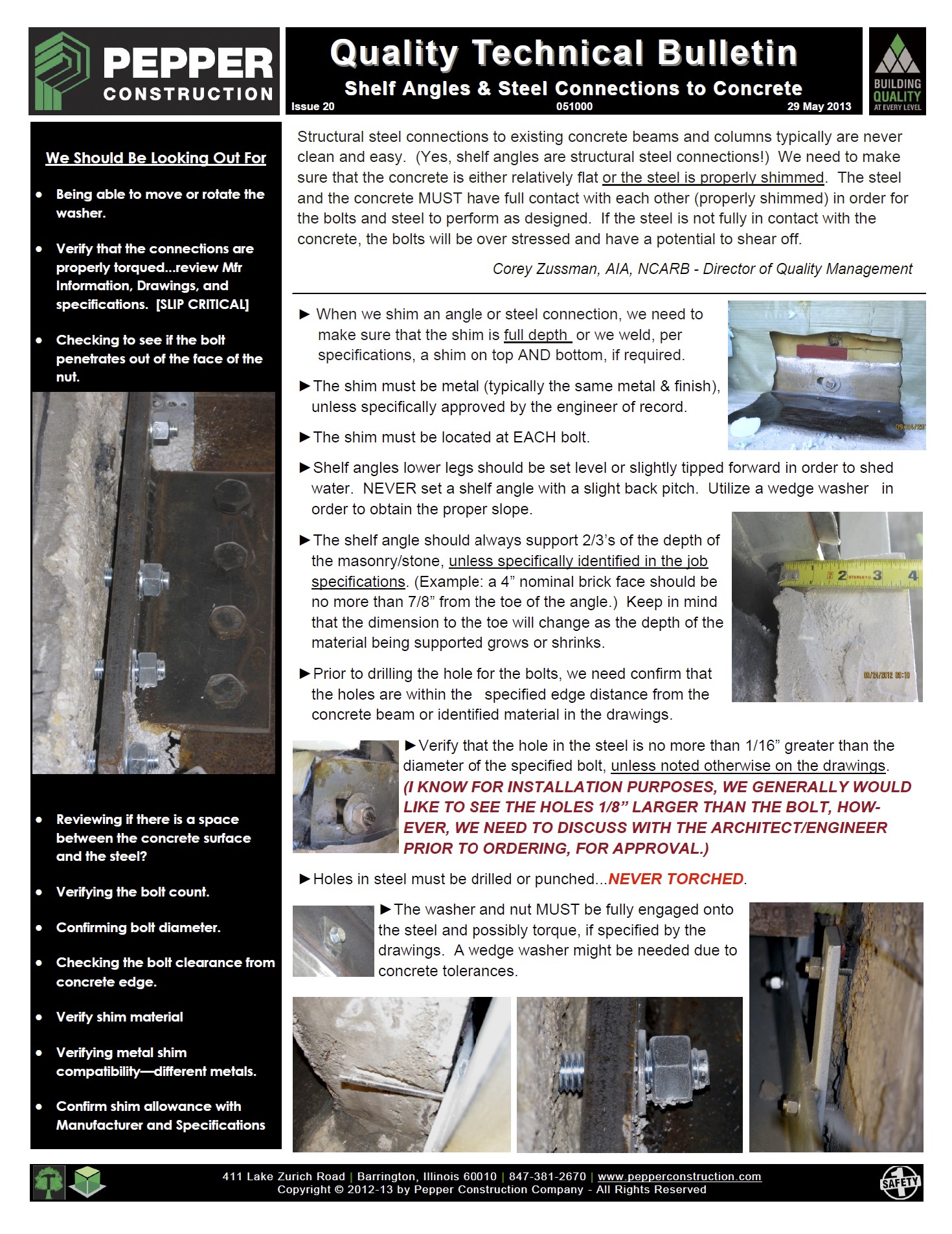

Masonry Shelf Angles - Issue 20

- Corey S Zussman, AIA

- Link

Structural steel connections to existing concrete beams and columns typically are never clean and easy. (Yes, shelf angles are structural steel connections!) We need to make sure that the concrete is either relatively flat or the steel is properly shimmed. The steel and the concrete MUST have full contact with each other (properly shimmed) in order for the bolts and steel to perform as designed. If the steel is not fully in contact with the concrete, the bolts will be over stressed and have a potential to shear off.

Masonry Mock-up 01 Constructability - QN

- Corey S Zussman, AIA

- Link

Masonry mock-ups are an important aspect of construction. There are two types of mock-ups: Owner/Architect Review & Constructability Mock-ups. The constructability mock-up is typically not in the specifications and it will provide Pepper and our subcontractor with the most information about the workmanship.

CMU Rebar Installation 01 - QN

- Corey S Zussman, AIA

- Link

In general, rebars are required to be located with-in the center of the CMU cell, as detailed by the Engineer.

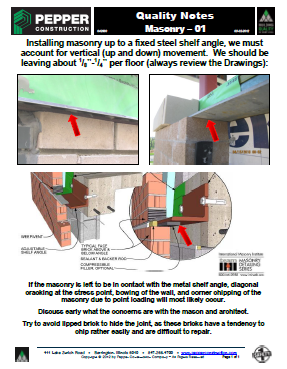

Masonry 01 Shelf Angles - QN

- Corey S Zussman, AIA

- Link

Installing masonry up to a fixed steel shelf angle, we must account for vertical (up and down) movement. We should be leaving about 1/8” - 1/4” per floor (always review the Drawings).

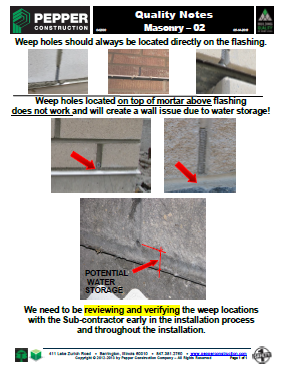

Masonry 02 Weep Holes - QN

- Corey S Zussman, AIA

- Link

When installing masonry, a lift or stage is installed with “tiebacks” to the building, typically with the wall built around the “tieback” and corrected later.

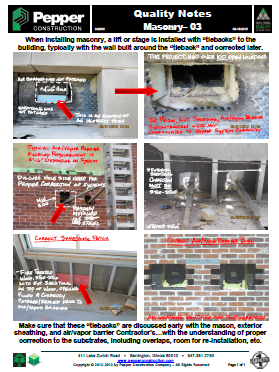

Masonry 03 Tie Back Concern - QN

- Corey S Zussman, AIA

- Link

When installing masonry, a lift or stage is installed with “tiebacks” to the building, typically with the wall built around the “tieback” and corrected later.

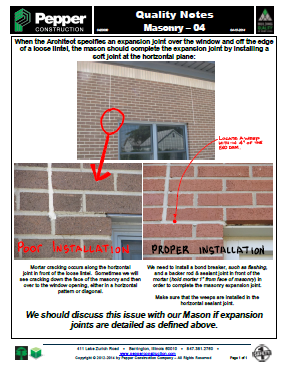

Masonry 04 Lintel Expansion Joint - QN

- Corey S Zussman, AIA

- Link

When the Architect specifies an expansion joint over the window and off the edge of a loose lintel, the mason should complete the expansion joint by installing a soft joint at the horizontal plane.

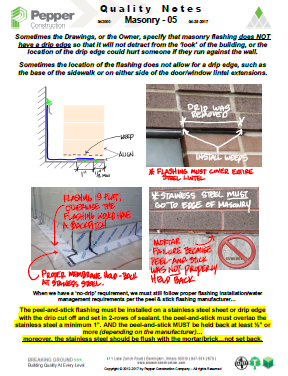

Masonry 05 No Drip Edge over Doors - QN

- Corey S Zussman, AIA

- Link

Sometimes the Drawings, or the Owner, specify that masonry flashing does NOT have a drip edge so that it will not detract from the ‘look’ of the building, or the location of the drip edge could hurt someone if they run against the wall.Sometimes the location of the flashing does not allow for a drip edge, such as the base of the sidewalk or on either side of the door/window lintel extensions.

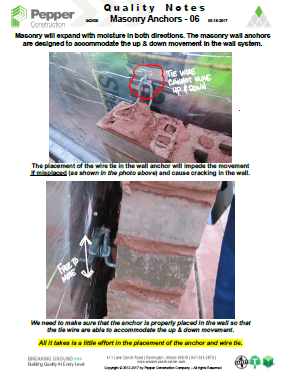

Masonry 06 Anchors Installation - QN

- Corey S Zussman, AIA

- Link

Masonry will expand with moisture in both directions. The masonry wall anchors are designed to accommodate the up & down movement in the wall system.

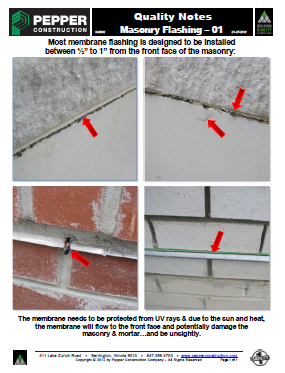

Masonry Flashing 01 Projection (Hold Back Requirements)- QN

- Corey S Zussman, AIA

- Link

Most membrane flashing is designed to be installed between ½” to 1” from the front face of the masonry.

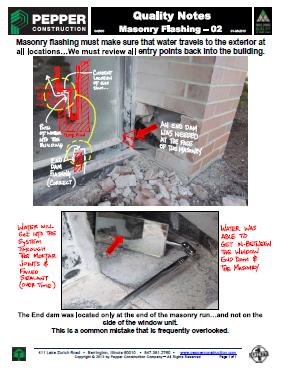

Masonry Flashing 02 End Dam within Wing Wall - QN

- Corey S Zussman, AIA

- Link

Masonry flashing must make sure that water travels to the exterior at all locations. We must review all entry points back into the building.

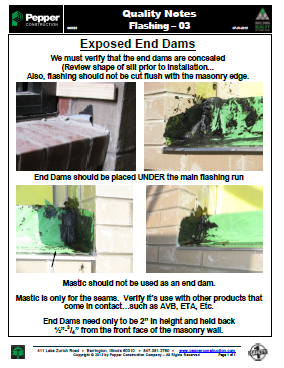

Masonry Flashing 03 Exposed End Dams - QN

- Corey S Zussman, AIA

- Link

We must verify that the end dams are concealed. Review shape of sill prior to installation. Also, flashing should not be cut flush with the masonry edge.

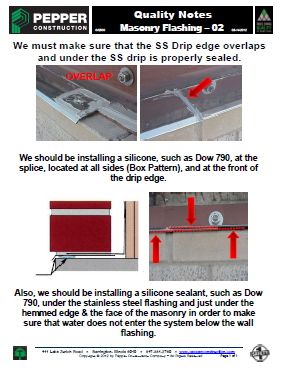

Masonry Flashing 04 SS Drip Splice - QN

- Corey S Zussman, AIA

- Link

We must make sure that the SS Drip edge overlaps and under the SS drip is properly sealed.

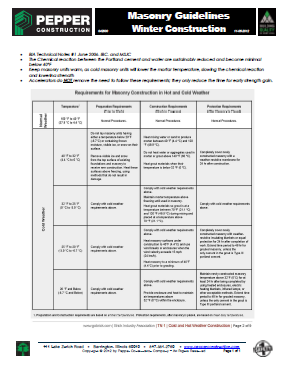

Winter Masonry Installation - QN

- Corey S Zussman, AIA

- Link

Requirements for masonry construction in hot and cold weather.

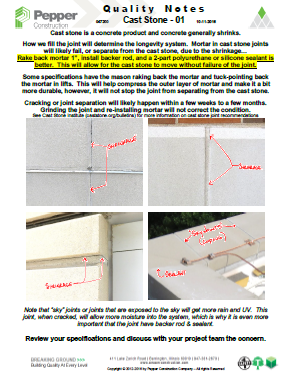

Cast Stone Joints 01 - QN

- Corey S Zussman, AIA

- Link

Cast stone is a concrete product and concrete generally shrinks. How we fill the joint will determine the longevity system.

Masonry and Limestone Tolerance

- Corey S Zussman, AIA

- Link

When designing the building envelope, we need to take into account the constructability and tolerance of the materials, components, and systems. Each material has a tolerance from material fabrication, component installation, as well as system installation tolerance. There are more tolerance allowances indicated in the referenced standards.

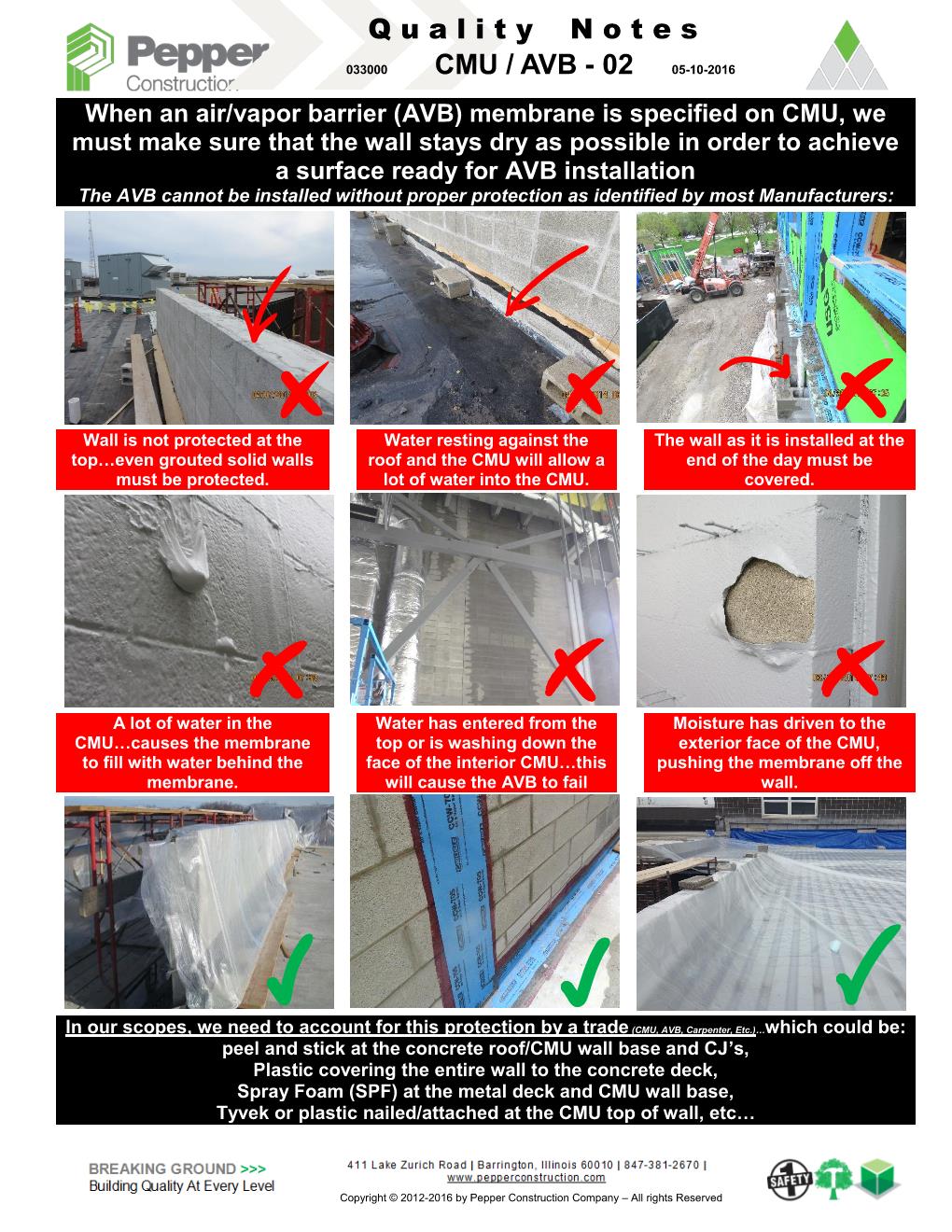

CMU Protection for AVB 02 QN

- Corey S Zussman, AIA

- Link

When an air/vapor barrier (AVB) membrane is specified on CMU, we must make sure that the wall stays dry as possible in order to achieve a surface ready for AVB installation The AVB cannot be installed without proper protection as identified by most Manufacturers.

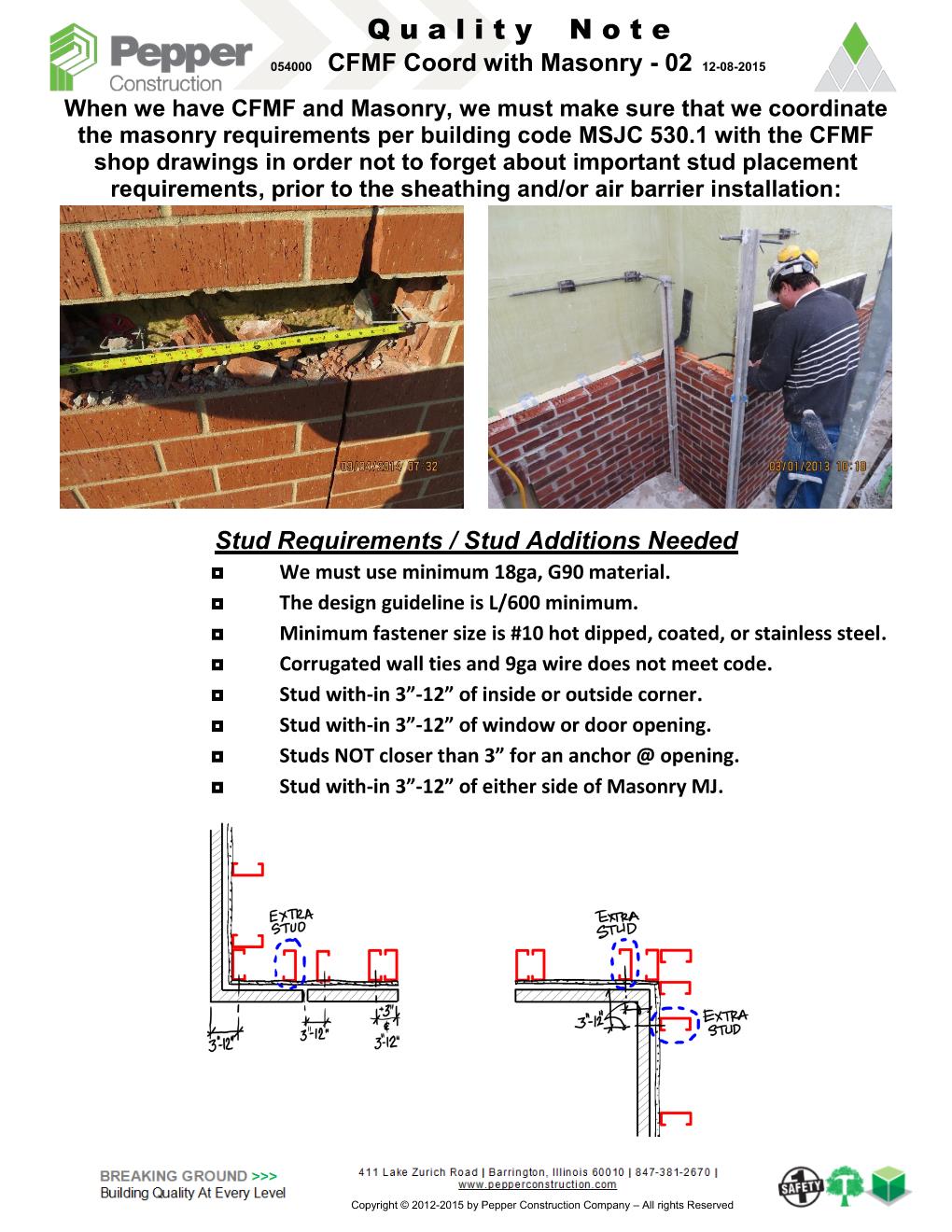

Masonry Coordination with CFMF QN

- Corey S Zussman, AIA

- Link

When we have CFMF and Masonry, we must make sure that we coordinate the masonry requirements per building code MSJC 530.1 with the CFMF shop drawings in order not to forget about important stud placement requirements, prior to the sheathing and/or air barrier installation.

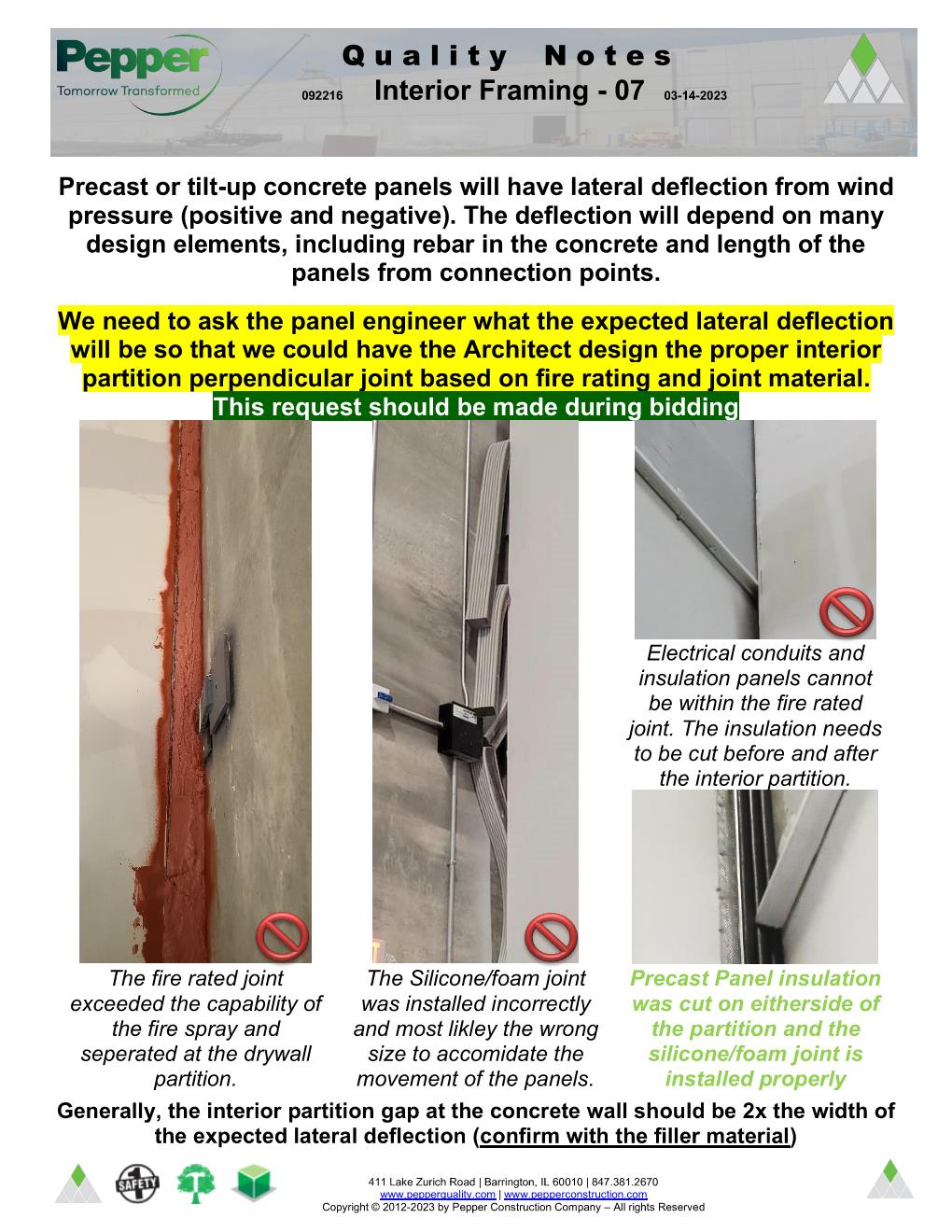

Precast Concrete and Interior Wall - Lateral Deflection QN

- Corey S Zussman, AIA

- Link

Precast or tilt-up concrete panels will have lateral deflection from wind pressure (positive and negative). The deflection will depend on many design elements, including rebar in the concrete and length of the panels from connection points. We need to ask the panel engineer what the expected lateral deflection will be so that we could have the Architect design the proper interior partition perpendicular joint based on fire rating and joint material.

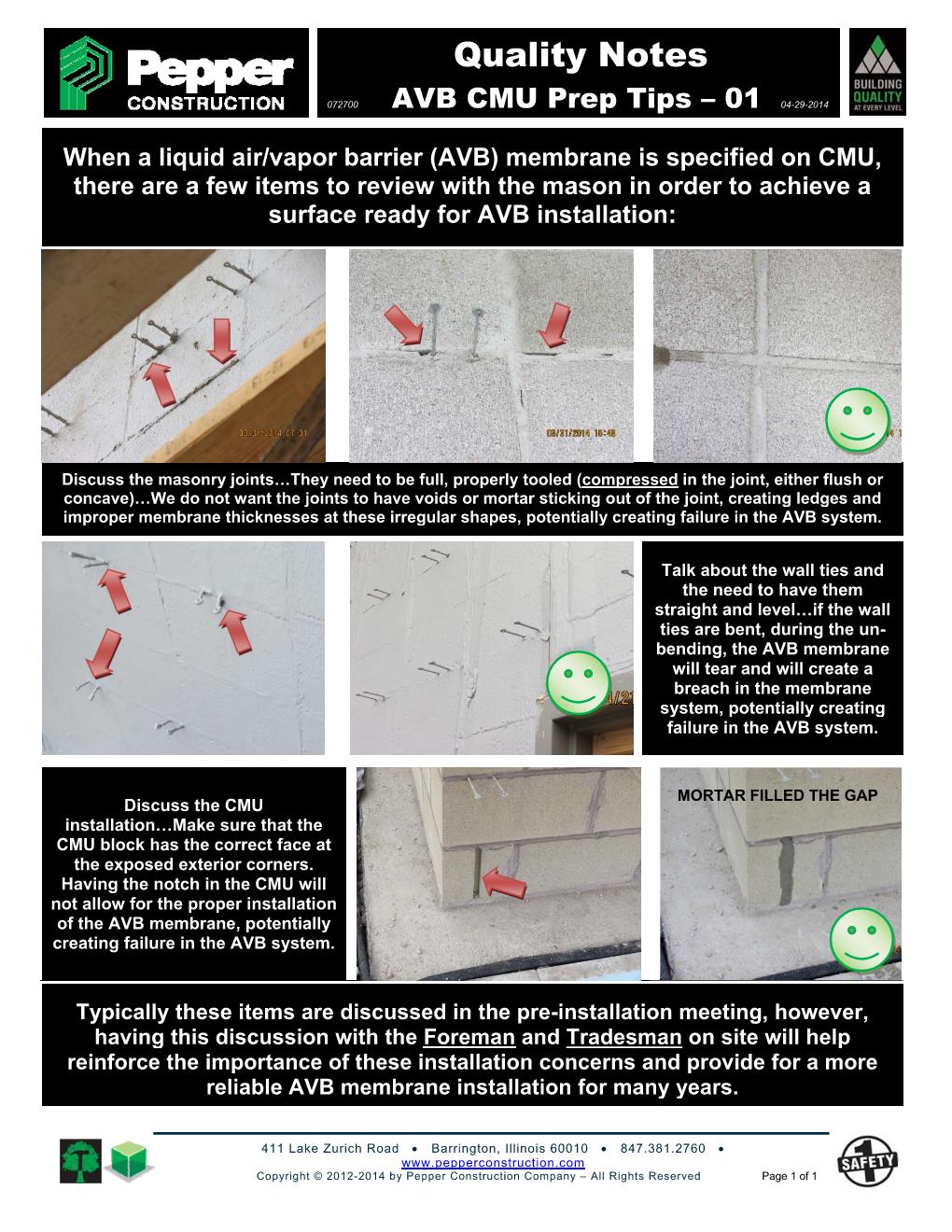

CMU Preparation for AVB QN

- Corey S Zussman, AIA

- Link

When a liquid air/vapor barrier (AVB) membrane is specified on CMU, there are a few items to review with the mason in order to achieve a surface ready for AVB installation.

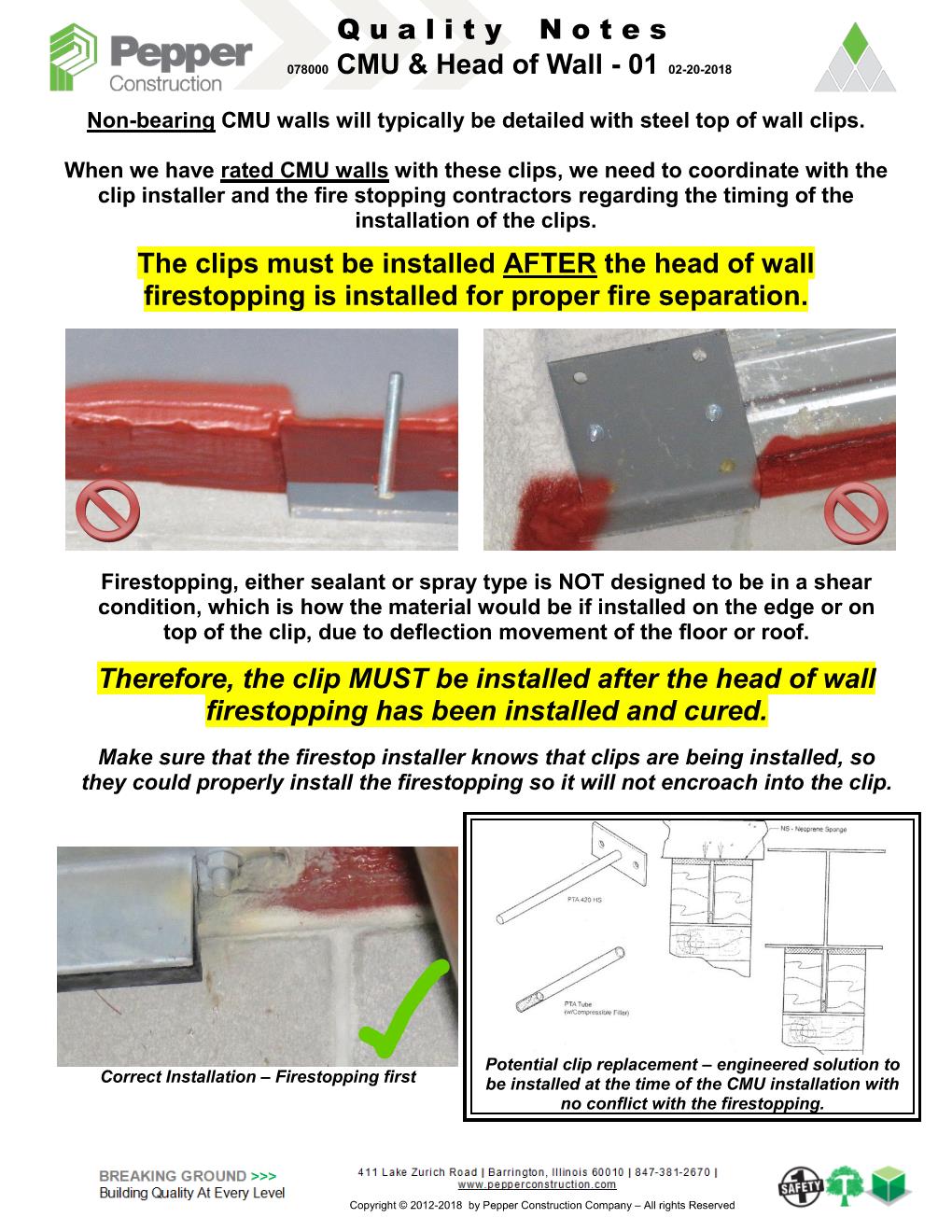

CMU Fire Rated Head of Wall QN

- Corey S Zussman, AIA

- Link

Non-bearing CMU walls will typically be detailed with steel top-of-wall clips. When we have rated CMU walls with these clips, we need to coordinate with the clip installer and the fire-stopping contractors regarding the timing of the clips installation. The clips must be installed AFTER the head of wall firestopping is installed for proper fire separation.